研究者紹介

Researcher

工学研究科

システム工学専攻

ZHANG ZHILIANG

- 研究テーマResearch theme

- Development of shipbuilding support system for linear heating forming of steel plates

- 研究内容の概要Overview

- This study proposes an innovative method based on machine learning and deep learning technology to optimize the heating line planning of steel plates in hull construction, thereby improving the accuracy and efficiency of steel plate forming.

The traditional linear heating process of steel plates relies on experienced workers to plan and adjust the heating lines. This process is time-consuming and requires multiple iterations, resulting in a waste of manpower and resources. To solve this problem, this study proposes an automated heating line planning method to achieve efficient heating of steel plates through machine learning and multi-objective optimization.

This study introduces a reinforcement learning algorithm (RL), principal component analysis particle swarm optimization algorithm (PCA-PSO) and deep Q network (DQN) algorithm to adaptively learn the optimal heating path based on the shape requirements of the target steel plate to minimize the forming error. There algorithms gradually optimizes the heating path through multiple iterations to ensure that the deformation of the steel plate is consistent with the target shape, thereby reducing manual intervention and improving the automation level of the heating process.

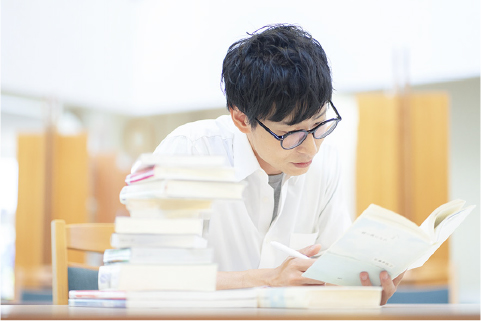

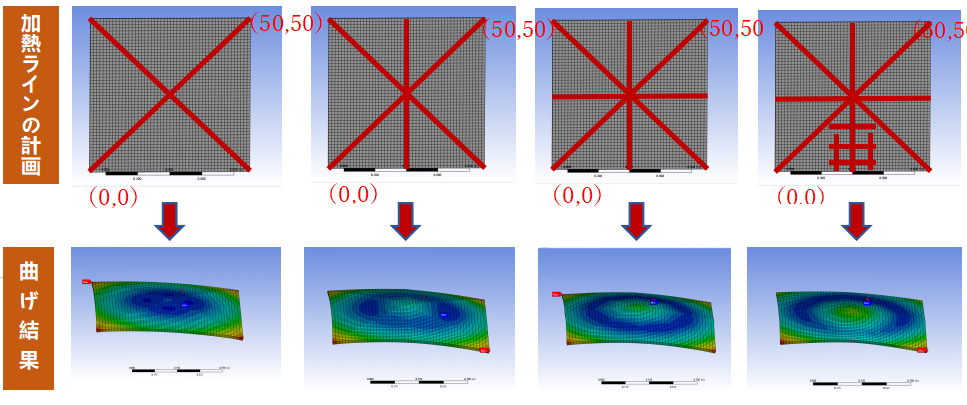

Reasonable heating line planning can not only reduce the repeated heating of the steel plate, but also improve the forming efficiency and accuracy, thereby further reducing the cost of the enterprise. Therefore, this study studied and conducted in-depth research on the heating and forming of steel plates and the planning of heating lines. The heating process was simulated using ANSYS software to generate relevant data, including the size of the steel plate, the division of the grid, the heating temperature, and the deformation and stress of the steel plate. The generated data was used to establish a heating line planning model and perform process optimization. Some steel plates cannot meet the forming requirements by heating once. Therefore, for multiple steel plate heating and forming. The designed steel plate heating line planning robot is shown in Figure 1. The designed hull steel plate hot forming support system is shown in Figure 2.

The methods can significantly improve the efficiency and accuracy of steel plate forming, reduce the dependence on experienced workers, reduce energy consumption and production costs, and has important engineering application value. This method provides an efficient and intelligent solution for steel plate heating in shipbuilding, which helps promote the digital transformation and upgrading of the shipbuilding industry.

Figure 1 Steel plate heating line planning robot

Figure 2 hull steel plate hot forming support system

- 研究成果をどのように社会に役立てるか

(還元の構想)Giving back to society - If this research is successfully used in actual projects, it can realize online detection of the forming status of steel plates. And the heating line planning and heating forming can be carried out according to the target shape of the steel plate. It can not only improve the processing efficiency of workers but also improve the forming accuracy. It can reduce redundant heating and energy waste, thereby reducing enterprise costs.